Watch this video to learn more about the very capable DA-130N Portable Density Meter.

DA-130N Portable Density Meter Review

By Hank Levi on Tue, Sep 24, 2019 @ 04:17 PM

The DA-130N portable density meter has twelve measurement modes and includes density of alcohol

By Hank Levi on Mon, Aug 20, 2018 @ 09:20 AM

Hand held density meters are very useful tools. You can take them with you and perform any of these 12 tasks.

| 1) | Density | 5) | API | 9) | Baume |

| 2) | Comp. Density | 6) | Brix | 10) | Plato |

| 3) | SG(t/t) | 7) | Alcohol | 11) | Proof |

| 4) | SG | 8) | H2SO4 | 12) | Conc. |

(1) Measurement of density

(2) Measurement of temperature compensated density

(3) Measurement of specific gravity; Measurement of true specific gravity at displayed measurement temperature

(4) Measurement of specific gravity temperature compensated; Measurement of true specific gravity at preset temperature

(5) Measurement of API degree; Measurement of density or API degree compensated in temperature to 15 degree C or 60 degree F for the product group A, B or D.

Selection of temperature, 15 degree C or 60 degree F, will be automatically made when setting the temperature unit. Product group A: Crude oil

[Measurement of density: API A (Density) Product group B: Fuel, Petroleum products

[Measurement of density: API B (Density) Product group D: Lubricant

[Measurement of density: API D (Density)

(6) Measurement of Brix concentration

Measurement of API degree: API A (Degree)] Measurement of API degree: API B (Degree)] Measurement of API degree: API D (Degree)]

Measurement of Brix concentration (sucrose concentration expressed in weight %) based on density at 20 degree C

(7) Measurement of Alcohol concentration

Measurement of alcohol concentration of Ethanol/Water mixed system in wt % or vol % at 15 degree C or 20 degree C calculated from the density at the measurement temperature. When setting of temperature unit is Fahrenheit

Measurement of alcohol concentration of Ethanol/Water mixed system in wt % or vol % at 60 degree F calculated from the density at the measurement temperature.

(8) Measurement of sulfuric acid concentration

Measurement of sulfuric acid concentration in weight % from density measured at 20 degree C

(9) Measurement of Baume degree

Measurement of Baume degree at converted temperature from density value measured at the measurement temperature

(10) Measurement of Plato degree

Measurement of Plato degree at 20 degree C from density obtained at measurement temperature

(11) Measurement of Proof degree

Measurement of Proof degree at 60 degree F from density obtained at measurement temperature Proof degree is one of the units for alcohol content, and there is US Proof and British Proof

Proof (US) : Measure in US Proof unit (100v/v%=200 US Proof)

Proof (IP) : Measure in UK Proof unit (100v/v%=175 British Proof)

DA-130N portable density meter General Maintenance Guidelines

By Hank Levi on Tue, Jul 31, 2018 @ 03:18 PM

This is a quick guide to getting started and running your first test. We thought it would be helpful for those getting started and checking their first calibration before running tests with actual samples. We will also continue to explore and share more information about calibration options, general maintenance, and data export methods using the DA-130N portable density meter.

O.K. Let's install three 'AAA' batteries to get started.

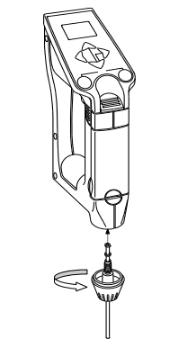

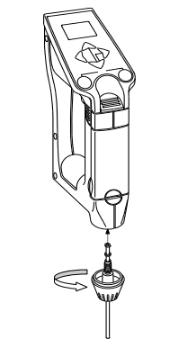

And then attach the sampling nozzle.

A few words about precautions when taking test measurements.

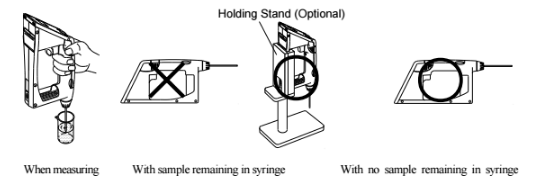

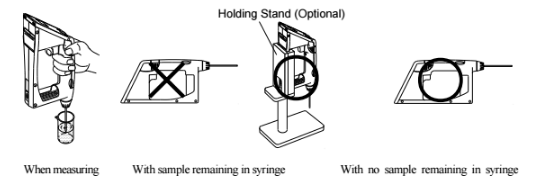

When measuring a sample make sure to hold the instrument so that the sampling nozzle is vertical to the ground. When laying down the instrument between or after measurements make sure to drain the remaining sample from the built-in syring (the built-in syringe is located inside the meter right above the sampling nozzle).

Now let's run a preliminary test using water.

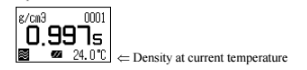

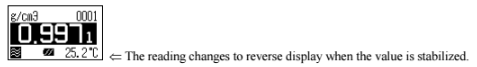

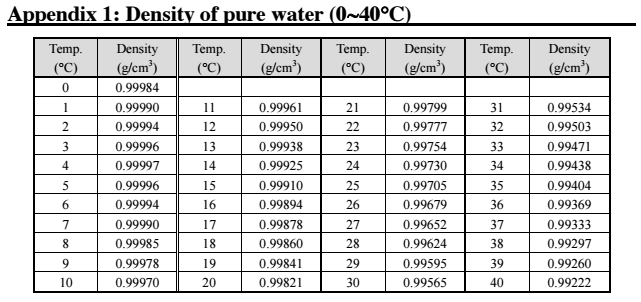

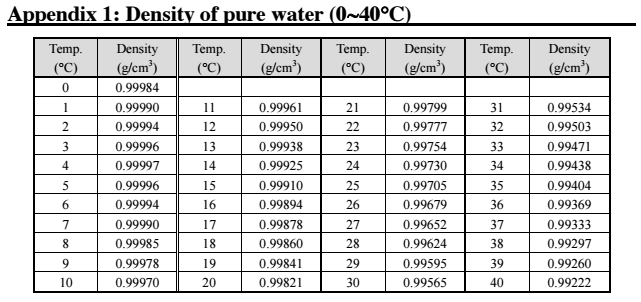

Calibration of the measuring cell using pure water

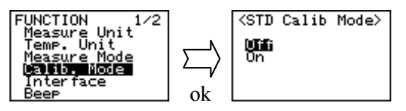

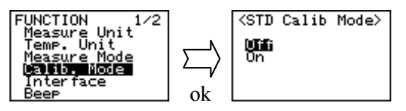

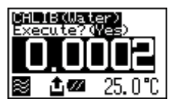

Set calibration mode to OFF. Press the [esc] key 2 times to return to the main menu. Sample pure water making sure no air bubbles are visible. The measuring cell with pure water can be calibrated automatically with the key entries as follows: Press [cal.] key for more than 2 seconds to show CALIB(Water) (inversed colo on the display) showing calibration with pure water in progress.

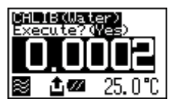

After calibration is over the deviation from the theoretical value will be shown so that you can check if the calibration has been successfully completed.

Note: if after attempting re-calibration of the measuring cell and results are still not within specifications it is possible the measuring cell itself is contaminated. In this case ensure to carefully clean the measuring cell and then re-calibrate again.

Note 1: You can also calibrate with a standard liquid that has a known density. Sometimes calibrating with a liquid that has a similar density to your test samples will help improve precision.

Note 2: You can also calibrate with air.

General maintenance - How to clean and dry the measuring cell and replace the built-in syringe

Step 1: Clean the measuring cell

You can thoroughly clean the measuring cell with just pure water. You can also improve the cleaning of the measuring cell by using Ethyl Alcohol. Ethyl Alcohol gets rid of dirt that cannot be removed with pure water and also reduces the amount of time to dry the measuring cell.

- Estimate 5 to 10 minutes for the measuring cell to dry after cleaning with pure water

- Estimate 3 to 5 minutes for the measuring cell to dry after cleaning with Ethyl Alcoho

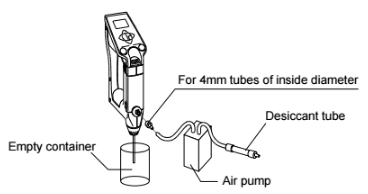

Step 2: Purge air to dry the cell thoroughly and completely

option using an air pump:

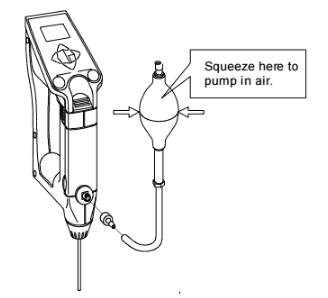

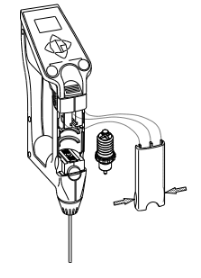

OR use the optional manual pump to dry the cell:

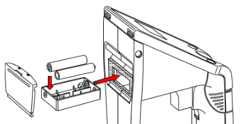

When using the optional manual pump to dry the cell make sure to clean the cell first and then press the sample discharging lever all the way down, and push the sample intake lever upward to lock it. With the adapter for the syringe attached connect the kit as illustrated above and feed air forcefully using the manual bulb.

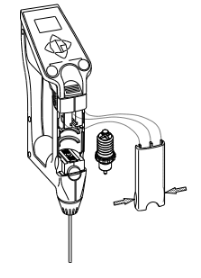

How to replace the built-in syringe.

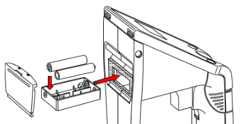

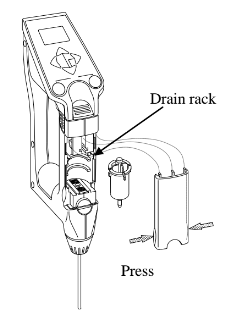

- Press down the sample discharging lever all the way and remove the syringe cover by pulling it toward you as illustrated.

- Turn the syringe 45degrees counter clockwise to release it from the o-ring.

- Slightly pull the sample drain-out lever toward you to pull out the syringe from the o-ring.

- Remove the syringe from the drain rack and replace it with a new one.

- Pull down the drain rack and insert the o-ring and turn it back clockwise until it stops.

- Place the syringe cover back on the unit.

Data Processing and Storage

The maximum number of data which can be stored in the DA-130N memory is 1,100 samples. Data can be set to be saved automatically or manually after each test. You can recall stored measurement data on the DA-130N display again or output the data to a printer or PC.

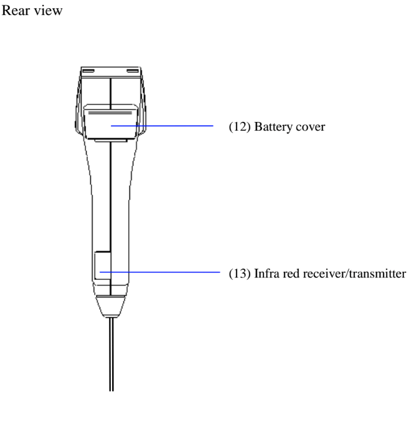

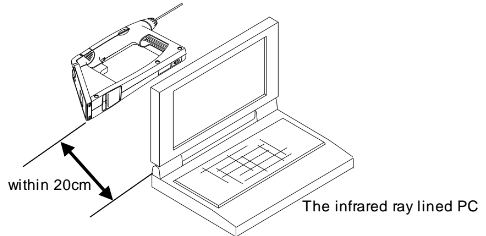

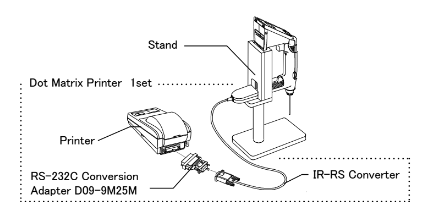

Exporting data to a PC via Infrared:

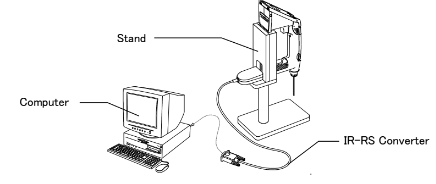

Exporting data to a PC via RS-232

Sending data to a printer:

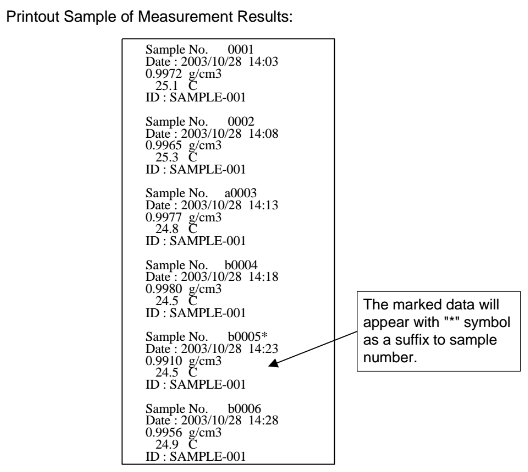

Example printout of data:

We hope this information about this particula density meter is helpful. If you need other capabilities beyond a traditional portable density meters refer to other bench top density meter models for increased accuracy.

Using the DA-130N portable density meter for the first time

By Hank Levi on Mon, May 15, 2017 @ 03:29 PM

This is a quick guide to getting started and running your first test. We thought it would be helpful for those getting started and checking their first calibration before running tests with actual samples. We will also continue to explore and share more information about calibration options, general maintenance, and data export methods using the DA-130N portable density meter in future posts.

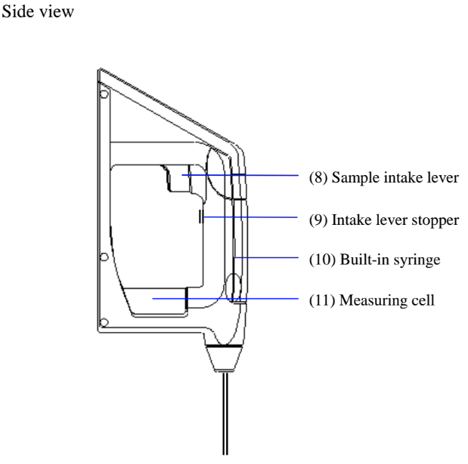

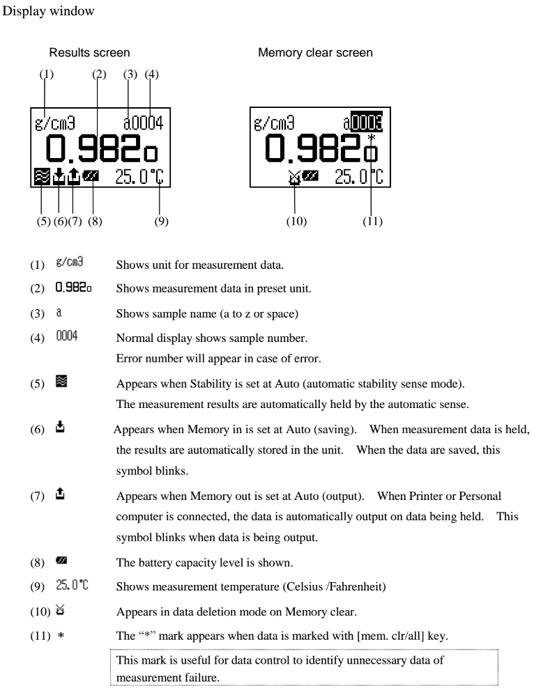

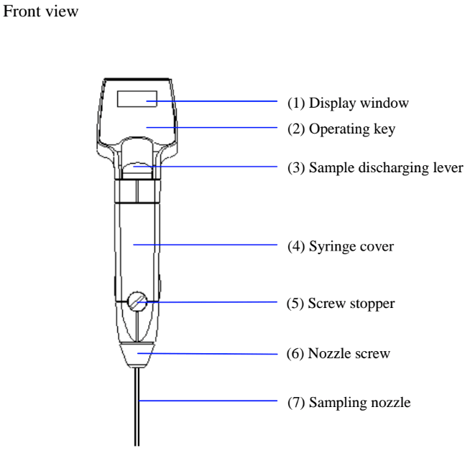

First, lets review and identify the parts of the DA-130N Portable Density Meter:

O.K. Now let's get started and install three 'AAA' batteries...

...And then attach the sampling nozzle.

A few words about precautions when taking test measurements.

When measuring a sample make sure to hold the instrument so that the sampling nozzle is vertical to the ground. When laying down the instrument between or after measurements make sure to drain the remaining sample from the built-in syring (the built-in syringe is located inside the meter right above the sampling nozzle).

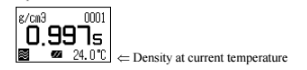

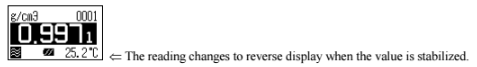

Now let's run a preliminary test using water.

- Make sure the sample discharging lever is pushed down to the bottom.

- If not, slowly push it down with your thumb.

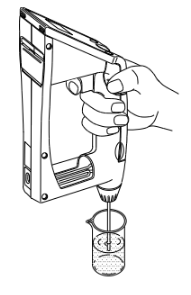

- Dip the sampling nozzle in the sample liquid.

- Slowly pull the sampling lever with the forefinger. When the cell is filled with sample, release your finger.

Calibration of the measuring cell using pure water

Set calibration mode to OFF. Press the [esc] key 2 times to return to the main menu. Sample pure water making sure no air bubbles are visible. The measuring cell with pure water can be calibrated automatically with the key entries as follows: Press [cal.] key for more than 2 seconds to show CALIB(Water) (inversed colo on the display) showing calibration with pure water in progress.

After calibration is over the deviation from the theoretical value will be shown so that you can check if the calibration has been successfully completed.

Note: if after attempting re-calibration of the measuring cell and results are still not within specifications it is possible the measuring cell itself is contaminated. In this case ensure to carefully clean the measuring cell and then re-calibrate again.

Note 1: You can also calibrate with a standard liquid that has a known density. Sometimes calibrating with a liquid that has a similar density to your test samples will help improve precision.

Note 2: You can also calibrate with air.

Some other useful things to know when working with different types of samples:

For more viscous samples over 2,000mPa.s it's a good idea to use the optional syringe adapter set. Almost any commerciall available syringe (plastic works great) will work. You just need to order the female adapter to make it work (Adapter part number is 12-04428-02)

When working with samples under 2,000mPa.s of viscosity but where samples contain particles or grains that may crystallize when dry we suggest you use the supplied bellows pump (swap out the built-in syringe for this).

We hope this information has been helpful!

5 ways we use liquid density information

By Hank Levi on Fri, Mar 20, 2015 @ 09:18 AM

5 ways we use liquid density information

Some background:

1. We live in a physical world

- >How much space does it take up?

- >How heavy is it?

- >How much of this can we put into that?

- >What is it?

- >Many everyday products are packaged by volume but sold by weight.

- >Predictive correlations can be made if you know the density.

- >If we change some of the ingredients that make up the fluid property will it change the weight?

The neat thing about understanding liquid density is that it can answer not only the three basic questions;

>What is the mass of the liquid?,

>What is the mass of the liquid?,- >what is the volume of the liquid?

- >What is the density of the liquid?

But also, What is the liquid?

2. You can use a liquids density to predict

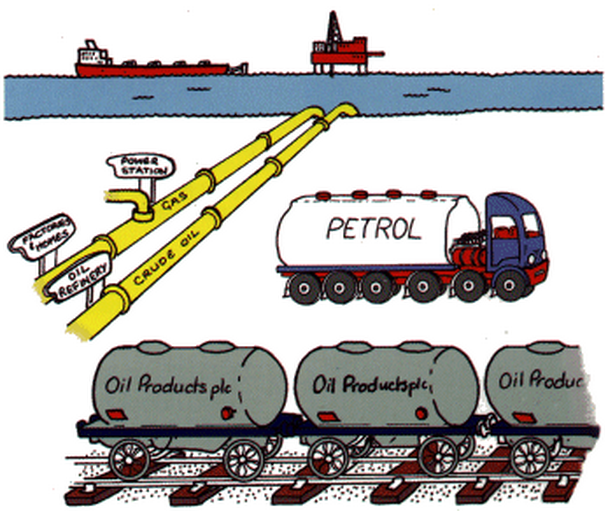

Fluid properties are probably even more telling where predictive3. Density helps us better understand how to transport fluids

4. Density helps set petroleum prices

Petroleum is used mostly by volume for the production of fuel, gasoline and

Petroleum is used mostly by volume for the production of fuel, gasoline and5. Density as it relates to gravity

Specific gravity

API gravity

⇒ Medium oil has an API gravity between 22.3 degrees API and 31.1 degrees API

⇒ Heavy oil has an API gravity below 22.3 degree API

⇒ Extra Heavy oil has an API gravity less than 10 degree API

CONCLUSION: