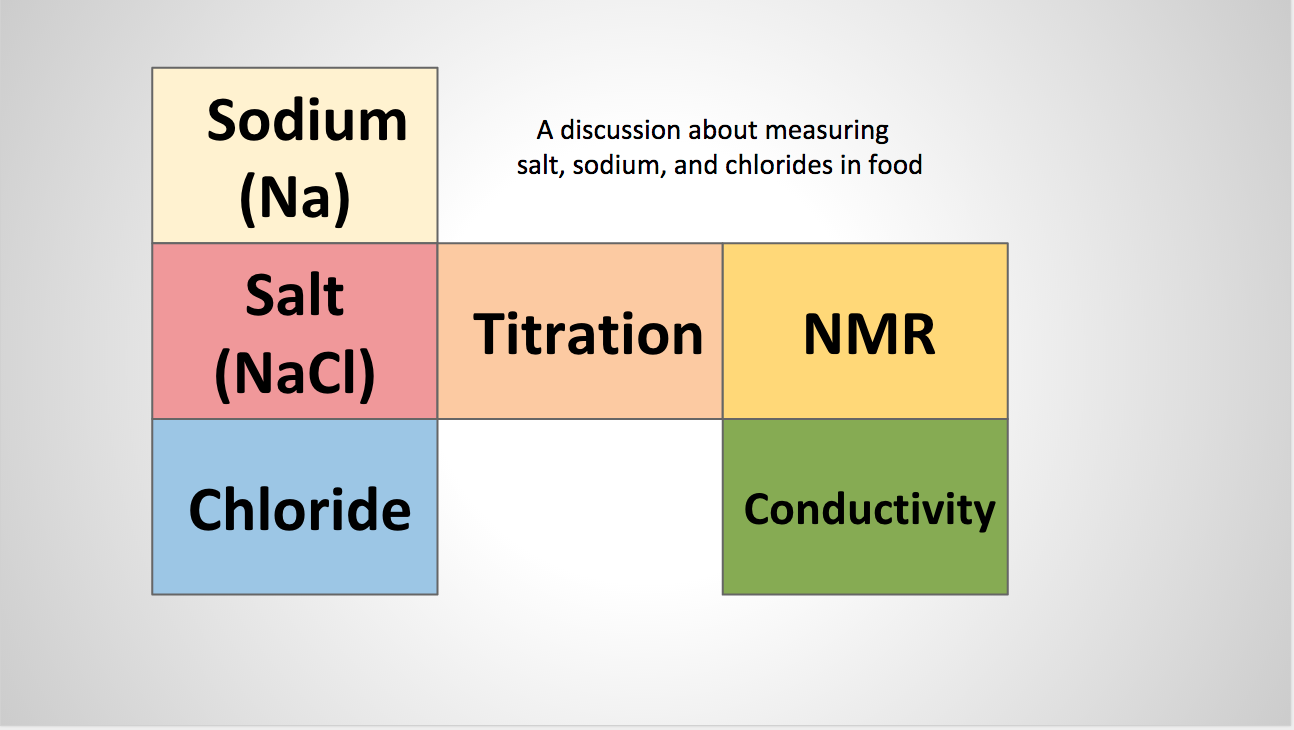

You may be saying to yourself, "Wait a minute! Last time you wrote about salt testing you said there were really only 2 popular methods being used. What's going on and what is this 3rd method all about?"

Well, you are right. Historically we have written about and discussed 2 popular methods where operators used either conductivity meters and, or, titration for testing salt in food products. But recently we have seen a new development for testing salt levels in food products and thought it should be shared with you. Before we do, let's review.

A quick overview on Salt:

When we talk about salt we need to agree on the terminology.

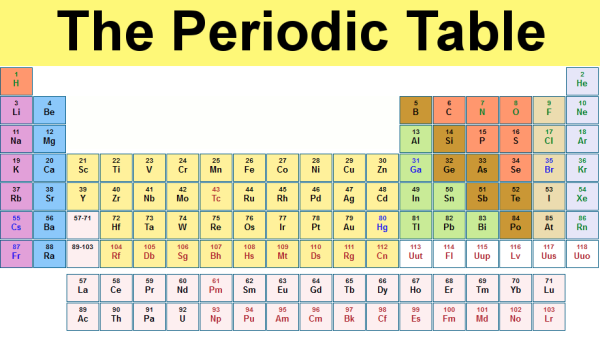

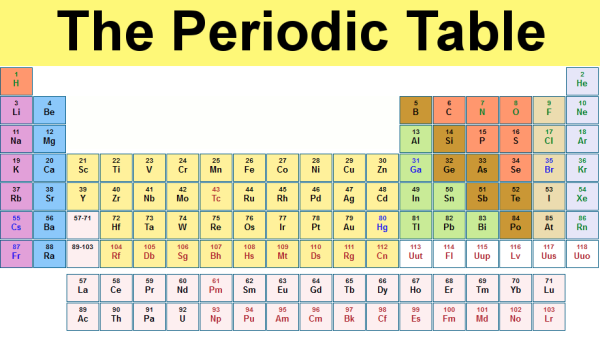

Table salt or "salt" that we think about in our foods is known as sodium chloride (NaCl). Although you cannot find NaCl on the periodic table of elements shown below, you can see both sodium (Na) and chlorine (Cl). What's the deal with chlorine you say? Well, chlorine under standard conditions is actually a yellow-green gas but when chlorine atoms gain one electron they become a chloride ion (Cl-). Since an ion cannot remain in a free state all by itself it must combine with another element(s) to form a compound. Chloride (Cl-) is therefore a by-product of the reaction between chlorine (Cl) and an electrolyte such as sodium (Na). Hence, sodium chloride (NaCl) is known as an Ionic Compound. There are other "related" chlorides (Ionic Compounds) but not as common and they are; calcium chloride, magnesium chloride and potassium chloride (we will save a discussion about these chlorides for another blog post).

Sodium chloride (NaCl) is naturally occurring in much of the earth's crust and can be found in places like the Great Salt Lake Basin in Utah. A gift to this earth, nature, and our bodies! You see, the human body needs both sodium and chloride to function properly although it's worth mentioning that there is still debate about the effects of chloride levels in the body as compared with the more well known negative effects we associate with sodium (Na) and high blood pressure.

with the more well known negative effects we associate with sodium (Na) and high blood pressure.

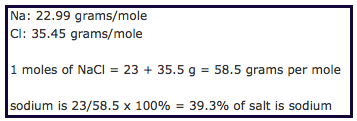

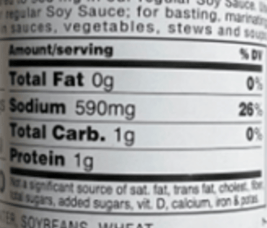

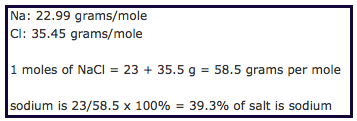

So, when we talk about measuring and monitoring salt levels we generally are saying that we want to know how much sodium (Na) is present. Since table salt is Na+Cl- (NaCl) then, we approach our testing for NaCl accordingly based on the ratios of each elements atomic weight and mass percent:

[NaCl = 39.3372% Na + 60.6628% Cl]

These numbers are significant because if we look for (Cl) then we can determine (Na) and or (NaCl) by doing simple math, e.g. if you can find (Cl) then you can back into (NaCl) or determine (Na).

So that's it for the salt review, lets move on to the testing methods.

Method #1 - A review of the Conductivity Method:

"Conductivity meters" are based on the conductivity of water and is a measure of the waters ability to pass an electrical current. Water with more ions present will conduct more electrical current. Seawater has more ions and is more conductive than fresh water. In our example for testing salt (NaCl) the chloride (Cl) readily dissolves in water. The fact that chloride (Cl) dissolves in water is key. The more chlorides (Cl) that dissolve, the greater the number of conductive ions that will be present and therefore increase the conductivity of the water, and vice versa for lesser amounts. The conductivity levels measured then are compared with known standards and tables like seawater. These numbers can then be reported in micro Siemens per centimeter or other conversion scales.

The conductivity method is an indirect measurement but it is easy and fast (several seconds). It tends to be less accurate than other methods and has some limitations with the range of measurement.

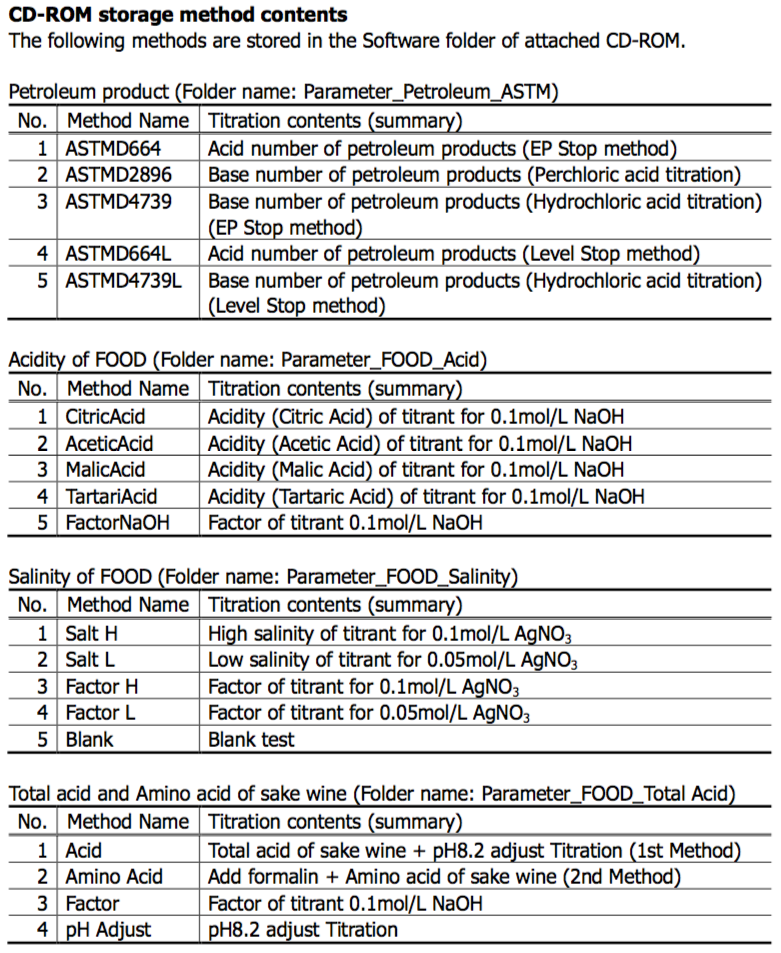

Method #2 - A review of the popular titration method (mohr's method):

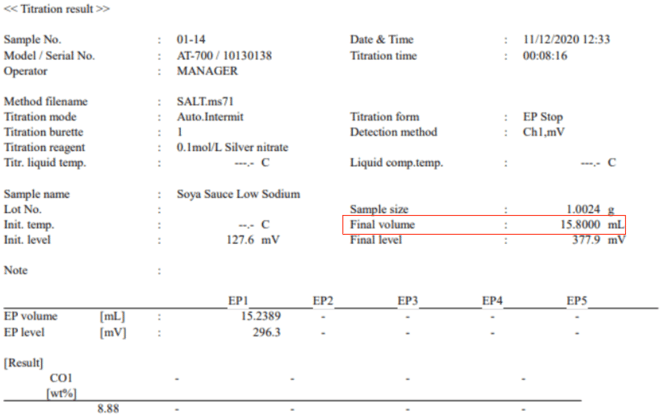

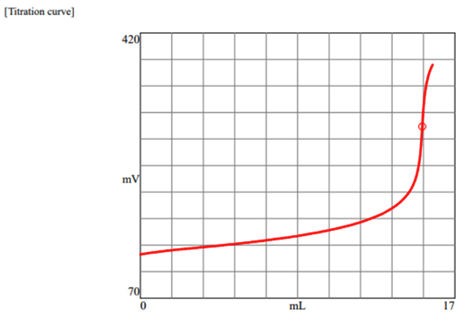

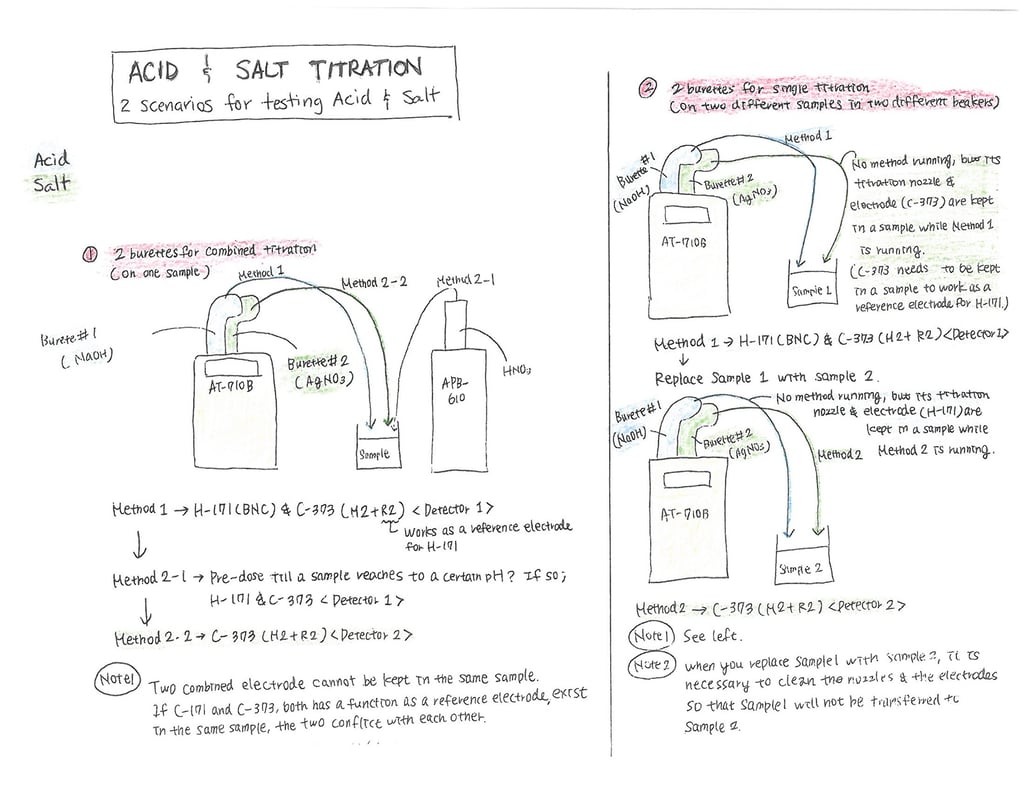

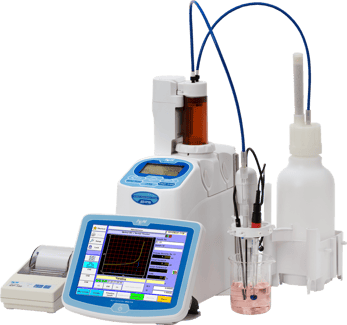

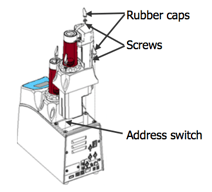

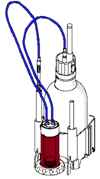

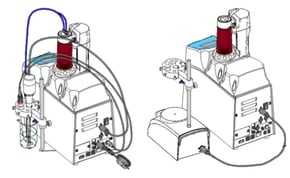

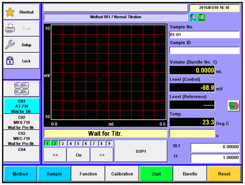

Titration can be performed manually or by using an automatic titrator. This popular titration method determines the chloride ion concentration. Silver nitrate is used as the indicator and is added until all of the chloride ions are precipitated. So, this method also measures the amount of chloride (Cl) and uses the mass percent weights to determine sodium chloride (NaCl) and or sodium (Na).

This method for measuring salt is more involved, takes a little more time (3 to 6 minutes usually), but is very accurate to the parts per million (PPM) level. The titration method does require the use of a silver electrode/ph electrode (or combined silver electrode), silver nitrate, and someone who understands how to run the method (manual or via automatic titrator).

Method #3 - A new method? Nuclear Magnetic Resonance (NMR):

Nuclear Magnetic Resonance (NMR)? Huh? Nuclear Magnetic Resonance (NMR) has been around since 1938 and has benefited the field of chemistry and medicine in important ways, helping researchers and chemist to identify and measure certain elements found on the periodic table.

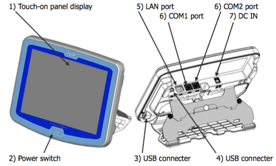

It's only now that technology has allowed for the miniaturization of the components (magnets, etc) necessary for making a benchtop NMR device. This greater access and ease of use with NMR technology has the potential not only for researchers and chemist but for main-stream industry to find new and useful applications for testing materials with NMR.

So, if you can see where this is going then, YES, you guessed it. NMR can identify and measure sodium (Na) directly with part per million (PPM) accuracy. I will say it again, this method measures total sodium (Na) directly with part per million (PPM) accuracy. (NaCl) and (Cl) can be determined also as we know the mass percentages for these elements.

Although it's a new concept for the food industry this new approach for measuring sodium could prove promising because it is easy, accurate to the part per million (PPM) level, and quick too (about 30 seconds per test).

with the more well known negative effects we associate with sodium (Na) and high blood pressure.

with the more well known negative effects we associate with sodium (Na) and high blood pressure.

Many companies produce the foods we eat. Do you ever wonder why or how they test for salt during the production process?

Many companies produce the foods we eat. Do you ever wonder why or how they test for salt during the production process?